Vision Control – SAW has been around since 2012 and today there are 52 systems operated around the world. the product has since begun to undergo a number of revisions and the focus has been on three areas:

1. To develop a market-leading and unique product.

2. To be able to handle measurements on all sawn products.

3. High measurement accuracy.

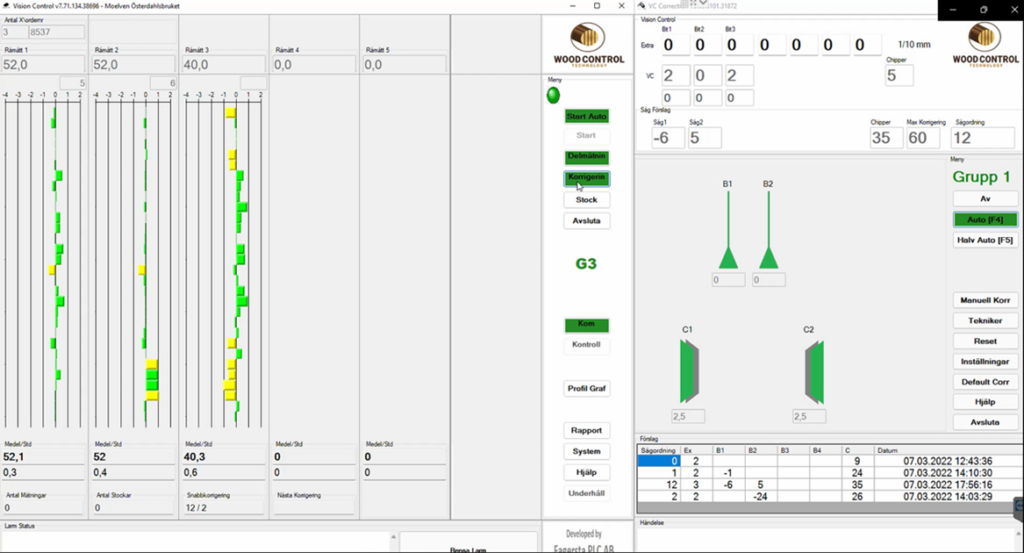

Many and complex program changes as well as mechanical improvements on the mechanical part have now been placed Vision Control – SAW in the front seat, as a fully developed product. In the latest revision, all intelligence lies in one’s own software. All analyzers and calculations of correction proposals are sent to the saw line’s PLC, for tuning the servos of the machines. A big focus has also been to keep the camera sensors from dirt over time. The housing is designed to minimize splashes and syringes that can enter the housing’s openings and a well-sized fan, gives a very high overpressure in the housing.

New functions for corrections have been developed in a side program, VCCorection and the program calculates unique corrections for each, different saw stand, ie the tools that have been engaged and produce each log / cant.